Shoes are an essential part of our daily attire, offering protection, comfort, and style. They come in various types, each designed for specific activities and occasions.

How Shoes Are Produced

The production of shoes involves a complex process that combines design, material selection, cutting, stitching, assembling, and finishing. This process can vary depending on the type of shoe being produced, such as athletic shoes, dress shoes, or casual footwear. Below is a detailed overview of the steps involved in the production of shoes.

1. Design and Development

The first step in shoe production is design and development. Designers create sketches or digital models of the shoe, taking into consideration current fashion trends, functionality, and the intended use of the shoe.

Design Process

- Concept Creation: Designers start with a concept, often inspired by fashion trends, customer feedback, or new technological advancements. This concept is translated into initial sketches or 3D digital models.

- Technical Drawings: Once the design concept is finalized, technical drawings are created. These include detailed specifications for materials, colors, and dimensions, which will guide the production process.

- Prototyping: A prototype or sample shoe is created based on the technical drawings. This allows designers to evaluate the design, make any necessary adjustments, and ensure the shoe meets both aesthetic and functional requirements.

2. Material Selection

Selecting the right materials is crucial to the quality and functionality of the shoe. Different types of shoes require different materials depending on their intended use.

Common Materials

- Leather: Used for high-quality dress shoes and boots. Leather is durable, breathable, and molds to the foot over time.

- Synthetic Materials: Often used in athletic and casual shoes. These materials can be lightweight, flexible, and resistant to water.

- Textiles: Fabrics such as canvas, mesh, and knit are used for their breathability and comfort, particularly in casual and athletic shoes.

- Rubber and EVA (Ethylene Vinyl Acetate): These materials are commonly used for soles due to their flexibility, cushioning, and durability.

3. Cutting and Preparation

Once the materials are selected, the next step is cutting the various components that will make up the shoe.

Cutting Process

- Pattern Making: Patterns for each part of the shoe, such as the upper, lining, and sole, are created based on the design specifications.

- Cutting: Using the patterns, the materials are cut into the required shapes. This can be done manually or with the help of cutting machines, such as die-cutters or laser cutters.

- Labeling and Sorting: The cut pieces are labeled and sorted according to size, style, and type, ready for the assembly process.

4. Stitching and Sewing

The cut pieces are then stitched together to form the upper part of the shoe, which is the portion that covers the top of the foot.

Stitching Process

- Assembling the Upper: The various components of the upper, such as the vamp, quarters, and tongue, are stitched together using industrial sewing machines. This process requires precision to ensure that the pieces fit together perfectly.

- Lining and Reinforcement: The lining and any necessary reinforcements, such as padding or stiffeners, are added during this stage to provide comfort and structure to the shoe.

- Attaching Decorative Elements: If the design includes decorative elements like embroidery, logos, or additional stitching patterns, these are added during the stitching process.

5. Lasting and Assembly

The shoe begins to take its final shape during the lasting and assembly process. The upper is combined with the sole to create the finished shoe.

Lasting Process

- Inserting the Last: A last, which is a mold shaped like a foot, is inserted into the stitched upper. The last gives the shoe its final shape and ensures that all components are correctly aligned.

- Shaping the Upper: The upper is stretched over the last and secured in place. This process is known as lasting and can be done manually or with lasting machines. The upper is then temporarily fixed to the insole with adhesive or tacks.

Assembly Process

- Attaching the Sole: The outsole is attached to the upper using adhesives, stitching, or both. In some cases, a midsole is added between the insole and outsole for additional cushioning and support.

- Heel Attachment: If the shoe has a heel, it is attached at this stage. The heel can be made from materials such as wood, rubber, or plastic, depending on the shoe’s design.

- Finishing the Edges: The edges of the sole and upper are trimmed and smoothed to ensure a clean finish.

6. Finishing

The final finishing touches are applied to the shoe, including cleaning, polishing, and quality inspection.

Finishing Process

- Cleaning and Polishing: The shoe is cleaned to remove any excess glue or marks from the production process. Depending on the material, it may also be polished or treated with a protective coating.

- Insole and Laces: The insole is inserted into the shoe, and any additional components, such as laces or buckles, are added.

- Branding and Packaging: Branding elements like logos or labels are attached, and the shoes are inspected for quality before being packaged for shipment.

7. Quality Control and Inspection

Quality control is a critical step in ensuring that each shoe meets the required standards before it reaches the customer.

Quality Control Steps

- Visual Inspection: The shoes are visually inspected for defects such as uneven stitching, incorrect assembly, or damage to materials.

- Fit Testing: Samples from each batch are tested on the last to ensure they meet the correct size and shape specifications.

- Durability Testing: In some cases, shoes undergo durability testing, which can include flexing, water resistance, and abrasion resistance tests.

8. Distribution and Retail

Once the shoes pass quality control, they are ready to be shipped to retailers or directly to customers.

Distribution Process

- Packaging: The shoes are packed in boxes, which may include additional elements like tissue paper, inserts, or protective covers to enhance presentation and protect the product during shipping.

- Shipping: Shoes are shipped to distribution centers or retail stores, where they are stocked for sale. In some cases, they are sent directly to customers who have placed orders online.

- Retail Display: In stores, shoes are displayed in a manner that highlights their design and features, encouraging customers to try them on and make a purchase.

Production Cost Distribution

The production cost of shoes typically includes:

- Materials (40-50%): This includes the upper materials (leather, fabric, synthetic), soles, insoles, and laces.

- Labor (20-30%): Costs related to cutting, sewing, assembling, and finishing the shoes.

- Manufacturing Overheads (10-15%): Includes costs for machinery, factory overheads, and quality control.

- Shipping and Logistics (5-10%): Costs associated with transporting raw materials and finished products.

- Marketing and Other Costs (5-10%): Includes marketing, packaging, and administrative expenses.

Types of Shoes

1. Sneakers

Overview

Sneakers are versatile and comfortable shoes designed for casual wear and physical activities. They are characterized by their rubber soles and flexible construction. Sneakers can be made from various materials, including leather, canvas, and synthetic fabrics, and often feature cushioned insoles and breathable linings.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Nike | 1964 | Beaverton, USA |

| Adidas | 1949 | Herzogenaurach, Germany |

| Puma | 1948 | Herzogenaurach, Germany |

| New Balance | 1906 | Boston, USA |

| Converse | 1908 | Boston, USA |

Averaged Retail Price on Amazon

- $60 – $150

Market Popularity

Sneakers are extremely popular worldwide due to their comfort, style, and versatility. They are worn by people of all ages and are suitable for various casual and athletic activities.

Production Details

- White Label Production Cost in China: $20.00 – $40.00 per unit

- Product Weight: 600 – 900 grams

- Minimum Order Quantity: 500 units

- Major Materials: Rubber, leather, synthetic fabrics, cushioned insoles

2. Dress Shoes

Overview

Dress shoes are designed for formal occasions and professional settings. They are typically made from high-quality leather and feature sleek, polished designs. Common types of dress shoes include oxfords, brogues, and loafers. These shoes often have leather soles and are meticulously crafted for a refined appearance.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Allen Edmonds | 1922 | Port Washington, USA |

| Johnston & Murphy | 1850 | Nashville, USA |

| Church’s | 1873 | Northampton, UK |

| Clarks | 1825 | Somerset, UK |

| Alden | 1884 | Middleborough, USA |

Averaged Retail Price on Amazon

- $100 – $300

Market Popularity

Dress shoes are highly popular among professionals and for formal events. They are favored for their sophisticated look and quality craftsmanship.

Production Details

- White Label Production Cost in China: $30.00 – $60.00 per unit

- Product Weight: 800 – 1000 grams

- Minimum Order Quantity: 300 units

- Major Materials: Leather, rubber, leather soles, stitching

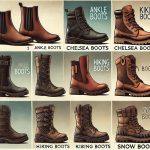

3. Boots

Overview

Boots are versatile footwear designed for protection and durability. They come in various styles, including ankle boots, knee-high boots, and work boots. Boots are typically made from sturdy materials like leather and synthetic fabrics, and often feature reinforced toes, rugged soles, and waterproof linings.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Timberland | 1952 | Stratham, USA |

| Dr. Martens | 1947 | Wollaston, UK |

| Red Wing Shoes | 1905 | Red Wing, USA |

| Caterpillar | 1925 | Deerfield, USA |

| UGG | 1978 | Goleta, USA |

Averaged Retail Price on Amazon

- $80 – $200

Market Popularity

Boots are popular for their durability and style. They are worn for various activities, including outdoor adventures, work, and casual outings.

Production Details

- White Label Production Cost in China: $25.00 – $50.00 per unit

- Product Weight: 1000 – 1500 grams

- Minimum Order Quantity: 300 units

- Major Materials: Leather, synthetic fabrics, rubber soles, waterproof linings

4. Sandals

Overview

Sandals are open-toed footwear designed for warm weather and casual wear. They are typically made from lightweight materials like leather, fabric, and synthetic materials. Sandals often feature straps, buckles, and cushioned soles for comfort and support.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Birkenstock | 1774 | Neustadt, Germany |

| Teva | 1984 | Flagstaff, USA |

| Chaco | 1989 | Rockford, USA |

| Clarks | 1825 | Somerset, UK |

| Havaianas | 1962 | São Paulo, Brazil |

Averaged Retail Price on Amazon

- $30 – $70

Market Popularity

Sandals are popular for their comfort and breathability. They are widely worn during the summer months and in warm climates.

Production Details

- White Label Production Cost in China: $8.00 – $15.00 per unit

- Product Weight: 200 – 400 grams

- Minimum Order Quantity: 500 units

- Major Materials: Leather, fabric, synthetic materials, rubber soles

5. Athletic Shoes

Overview

Athletic shoes are specifically designed for sports and physical activities. They provide support, stability, and cushioning to enhance performance and reduce the risk of injury. Athletic shoes come in various types, including running shoes, basketball shoes, and training shoes, each tailored to specific sports.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Nike | 1964 | Beaverton, USA |

| Adidas | 1949 | Herzogenaurach, Germany |

| Reebok | 1958 | Boston, USA |

| Under Armour | 1996 | Baltimore, USA |

| New Balance | 1906 | Boston, USA |

Averaged Retail Price on Amazon

- $60 – $150

Market Popularity

Athletic shoes are highly popular among athletes and fitness enthusiasts. They are essential for sports activities and are designed to provide optimal performance.

Production Details

- White Label Production Cost in China: $20.00 – $40.00 per unit

- Product Weight: 600 – 900 grams

- Minimum Order Quantity: 500 units

- Major Materials: Synthetic fabrics, rubber, cushioning materials, stitching

6. Casual Shoes

Overview

Casual shoes are designed for everyday wear, offering comfort and style. They come in various styles, including loafers, slip-ons, and boat shoes. Casual shoes are typically made from materials like leather, canvas, and synthetic fabrics, and often feature cushioned insoles and flexible soles.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Sperry | 1935 | Waltham, USA |

| TOMS | 2006 | Los Angeles, USA |

| Vans | 1966 | Anaheim, USA |

| Clarks | 1825 | Somerset, UK |

| Skechers | 1992 | Manhattan Beach, USA |

Averaged Retail Price on Amazon

- $40 – $100

Market Popularity

Casual shoes are popular for their comfort and versatility. They are suitable for various everyday activities and casual outings.

Production Details

- White Label Production Cost in China: $15.00 – $30.00 per unit

- Product Weight: 400 – 700 grams

- Minimum Order Quantity: 500 units

- Major Materials: Leather, canvas, synthetic fabrics, rubber soles

7. High Heels

Overview

High heels are a type of shoe characterized by a raised heel, often worn for formal occasions and professional settings. They come in various styles, including stilettos, pumps, and wedges. High heels are typically made from materials like leather, suede, and synthetic fabrics, and often feature decorative elements such as buckles, straps, and embellishments.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Jimmy Choo | 1996 | London, UK |

| Christian Louboutin | 1991 | Paris, France |

| Manolo Blahnik | 1970 | London, UK |

| Stuart Weitzman | 1986 | New York, USA |

| Nine West | 1978 | New York, USA |

Averaged Retail Price on Amazon

- $80 – $200

Market Popularity

High heels are popular among women for their elegance and ability to enhance the appearance of the legs. They are often worn for formal events and professional settings.

Production Details

- White Label Production Cost in China: $25.00 – $50.00 per unit

- Product Weight: 400 – 600 grams

- Minimum Order Quantity: 300 units

- Major Materials: Leather, suede, synthetic fabrics, decorative elements

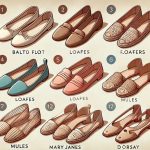

8. Loafers

Overview

Loafers are slip-on shoes known for their comfort and classic style. They come in various designs, including penny loafers, tassel loafers, and driving loafers. Loafers are typically made from leather, suede, and synthetic materials, and often feature minimalistic designs with decorative elements.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| Gucci | 1921 | Florence, Italy |

| Tod’s | 1920 | Sant’Elpidio a Mare, Italy |

| Cole Haan | 1928 | Chicago, USA |

| Clarks | 1825 | Somerset, UK |

| Johnston & Murphy | 1850 | Nashville, USA |

Averaged Retail Price on Amazon

- $60 – $150

Market Popularity

Loafers are popular for their comfort and versatility. They are suitable for both casual and semi-formal occasions, making them a staple in many wardrobes.

Production Details

- White Label Production Cost in China: $20.00 – $40.00 per unit

- Product Weight: 400 – 600 grams

- Minimum Order Quantity: 500 units

- Major Materials: Leather, suede, synthetic materials, rubber soles

9. Slippers

Overview

Slippers are soft, comfortable shoes designed for indoor wear. They come in various styles, including open-toe, closed-toe, and moccasin designs. Slippers are typically made from materials like cotton, wool, and synthetic fabrics, and often feature cushioned insoles and non-slip soles.

Popular Brands

| Brand | Established | Location |

|---|---|---|

| UGG | 1978 | Goleta, USA |

| Sorel | 1962 | Portland, USA |

| Dearfoams | 1947 | Columbus, USA |

| Acorn | 1976 | Lewiston, USA |

| Isotoner | 1910 | Cincinnati, USA |

Averaged Retail Price on Amazon

- $20 – $50

Market Popularity

Slippers are popular for their comfort and warmth. They are widely worn indoors for relaxation and lounging.

Production Details

- White Label Production Cost in China: $5.00 – $12.00 per unit

- Product Weight: 200 – 400 grams

- Minimum Order Quantity: 500 units

- Major Materials: Cotton, wool, synthetic fabrics, cushioned insoles, non-slip soles